EDM Cutting Services

EDM, or Electrical Discharge Machining, is a highly specialized manufacturing process used for precision machining of conductive materials. This process uses electrical discharges, or sparks, to erode material from the workpiece. EDM is particularly effective for hard materials that are challenging to machine using traditional methods, making it invaluable for creating intricate molds, dies, and complex components.

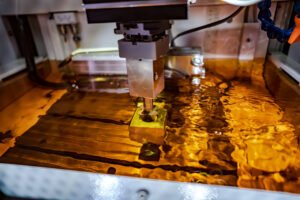

The process involves an electrode and the workpiece submerged in a dielectric fluid. The electrode delivers controlled electrical discharges to the workpiece, eroding it into the desired shape with high precision. EDM is known for its ability to produce extremely fine details and complex shapes with smooth surfaces, often eliminating the need for additional finishing.

Wire-Cut EDM

Wire-Cut EDM is a variation of Electrical Discharge Machining that uses a continuously moving thin wire as an electrode. This method is renowned for its exceptional precision and ability to produce intricate and delicate shapes in conductive materials. Wire-Cut EDM is ideal for manufacturing complex parts with tight tolerances and fine features.

In Wire-Cut EDM, the wire electrode, typically made of brass or stratified copper, moves through the workpiece and cuts the material in a controlled manner. This process is especially useful for creating complex 2D shapes, narrow slots, and sharp inside corners with a high degree of accuracy. The wire’s path is controlled by a CNC system, ensuring precision and repeatability in the cutting process.

Gallery

What Materials Can Be Machined Using EDM?

EDM is ideal for conductive materials, including hardened steel, titanium, and superalloys.

How Precise is EDM?

EDM offers high precision, capable of machining complex shapes with fine details and tolerances.

What are the Main Applications of EDM?

Key applications include tool and die making, aerospace components, and intricate medical devices.

What Advantages Does Wire-Cut EDM Offer?

Wire-Cut EDM excels in cutting intricate designs and achieving tight tolerances with a smooth surface finish.

Can Wire-Cut EDM Handle Hard Materials?

Yes, Wire-Cut EDM is particularly effective for hard materials that are difficult to machine with conventional methods.

What Industries Commonly Use Wire-Cut EDM?

Common industries include aerospace, automotive, tool making, and medical device manufacturing.

Contact

+91- 90035 99554

sales@cnve.in

Schedule a Call