Precision Machined Components

How Precision Machined Components Influences Modern Manufacturing

Machined parts are the core of almost every manufactured item, consumer or industrial, in our current society.

Precision in machining refers to the proximity of limits while making small parts for various machines and uses, whereas the conventional method concentrates on the creation of detailed characteristics. The automobile and aerospace industries demand faultless performance from these high-precision components.

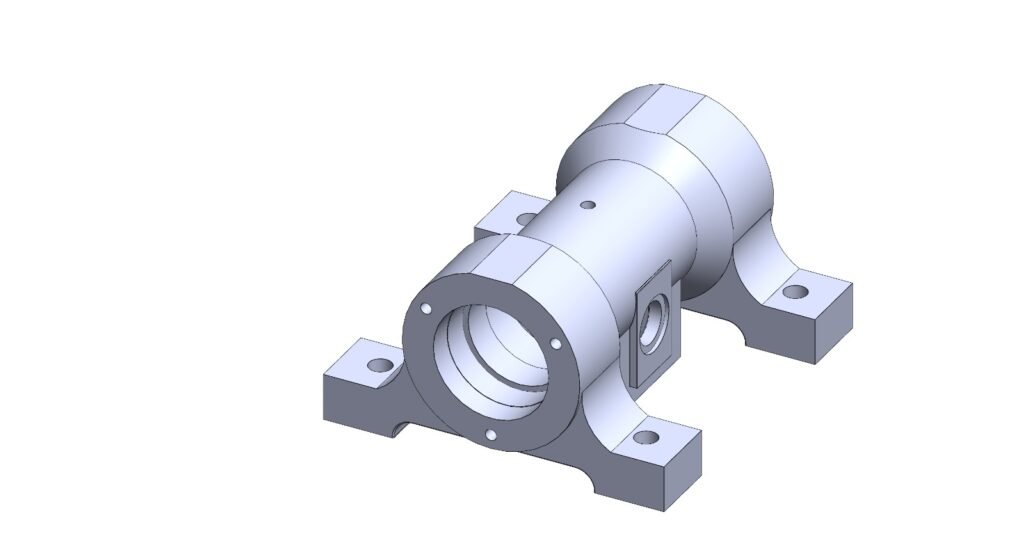

The Art of precision machining: From the idea drawn on paper to the final concept of the product

The entire process of producing a precision machined components starts with the design of the component in CAD software. Engineers draw on paper what is to be created and the drawings are taken to create 3D models that are input to CNC machines. This procedure makes it possible to produce hundreds of similar items and ensure size and shape are accurate to a fraction of one hundredth or a thousandth of a millimetre.

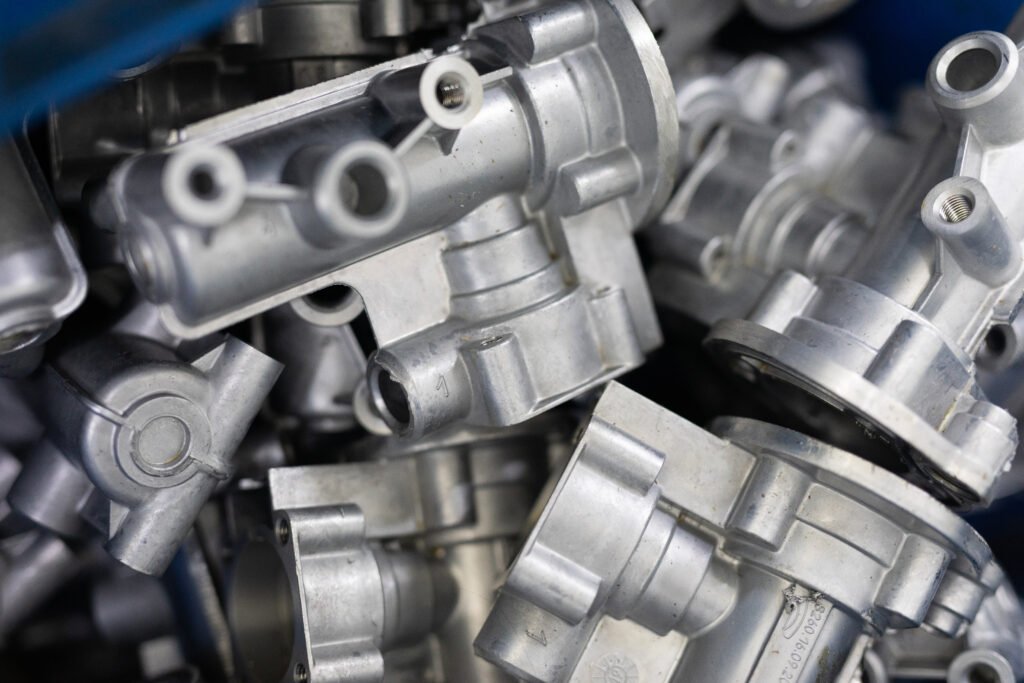

Industries dependent on precision machined components

There are several industries where the precision of the machined components has a significant voice.

• Aerospace: Components such as aircraft engines, landing gears, and flight control systems require very accurate machining to work as needed.

•Automotive: Pistons, crankshafts, and other internal and transmission components are precision-made to provide maximum power and life.

• Valve Industries: Valves in fluid control system designs are made with specific precision in sealing and flow control.

• Railway: Components like wheels and axles, brakes, and engine parts should have small clearances to operate safely and effectively.

• HVAC: Elements of a precision machined components have a consistent flow of air and other climate control factors.

• Oil and Gas: Environmentally sensitive equipment used in exploration and refinement, that works under intense pressure and high temperatures requires precise machining.

• General Engineering: Precision machined components are the fundamentals of numerous equipment and devices.

Beyond the Obvious

The benefits of precision machining extend beyond large industries:

Creating Custom Parts and Fasteners: High precision enables designers and manufacturers to develop custom parts for unique design work, prototyping, and repair activities.

Mass Production with Consistent Quality: Ensures uniformity of dimensional accuracy that has bearings on tractions, hence offering the needed performances.

Reduced Waste: Less waste is likely to occur since the cutting process will be done as per requirements, thus helping in environmental conservation.

Faster Assembly: Guarantees conformity with accurate dimensions that would make the assembly processes run efficiently.

Cost-effectiveness: Reduces the number of mistakes and do-overs, thereby cutting total manufacturing costs.

Safety: Accidents caused by manual machining may decrease since precision machining is computer-controlled.

Rapid Prototyping: Encourages functional prototypes, which will help verify design for manufacturing more quantity.

Contract Manufacturing: This uses the experience and setup for creating large quantities of precisely manufactured parts.

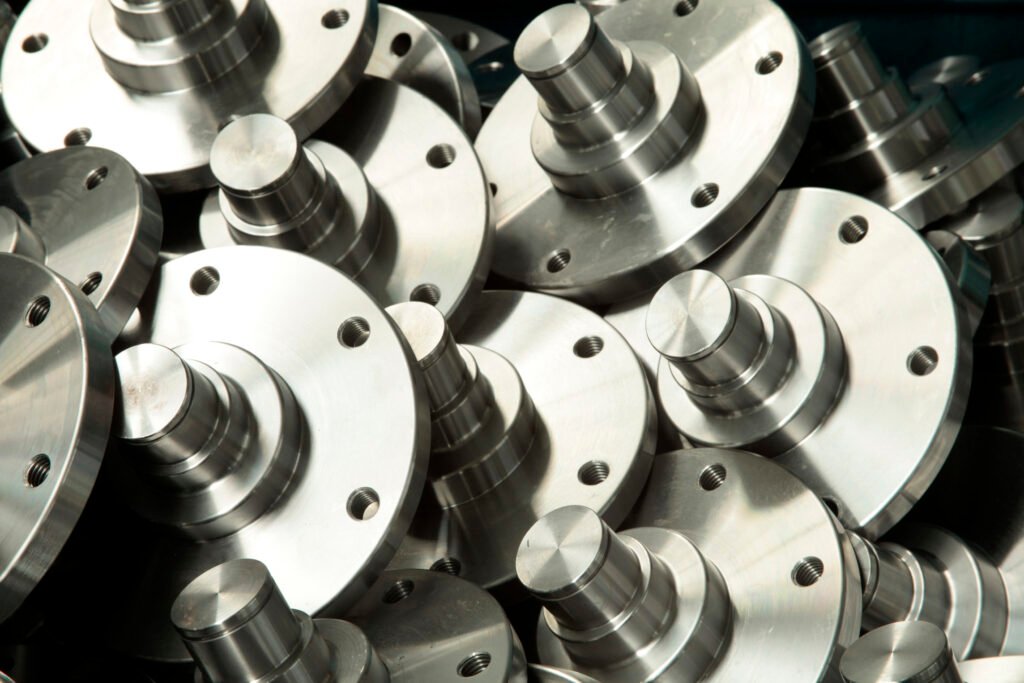

What materials can you machine?

We specialize in machining a wide range of materials, including but not limited to:

- Stainless Steel: Ideal for components requiring high strength and corrosion resistance.

- Aluminum: Lightweight and versatile, suitable for various applications.

- Exotic Alloys: Including titanium, Inconel, and other specialized materials for high-performance applications.

- Brass and Copper: Excellent for components requiring electrical conductivity and corrosion resistance.

Our expertise ensures that each material is machined to the precise specifications required for your application.

What are the typical tolerances you can achieve?

We can achieve extremely tight tolerances, typically within ±0.001 inches (±0.025 mm), depending on the specific requirements of the part. Our advanced CNC machining technology and rigorous process controls ensure that we consistently meet or exceed the tolerance standards required by our clients.

In one of the extreme accuracy requirement application, we have been able to consistently supply parts controlled within 13microns totally after phospating for more than 1 million parts at 0 PPM.

How do you ensure the quality of your machined components?

Quality is our top priority. We implement a comprehensive quality management system that includes:

- Process Control: Continuous monitoring and adjustment during production.

- Process Audits: Regular audits to ensure compliance with industry standards.

- Inspection: Detailed inspections at multiple stages of production using precision measurement tools like CMM (Coordinate Measuring Machines).

- 0 PPM Policy: We are committed to delivering zero-defect components, ensuring every part meets your exact specifications.

What is your lead time for precision machined components?

Lead times can vary depending on the complexity and volume of the order, but typically range from 2 to 6 weeks.

We prioritize clear communication with our clients to provide accurate lead time estimates and ensure timely delivery, even for urgent requirements.

Do you offer prototyping and small batch production?

Yes, we offer both prototyping and small batch production services. Our flexible manufacturing process allows us to accommodate low-volume production runs, making it easier for you to test and validate your designs before committing to full-scale production. We work closely with you to optimize the design for manufacturability and ensure that the prototype meets all your requirements.

Contact

+91- 90035 99554

sales@cnve.in

Schedule a Call